19

2025

-

05

D20 Audit Report

Author:

Audit Report

■QMS■ Initial Audit Stage Two

■QMS■ Initial Audit Stage Two

■EMS■ Initial Audit Stage Two

■EMS■ Initial Audit Stage Two

■OHSMS■ Initial Audit Stage Two

■OHSMS■ Initial Audit Stage Two

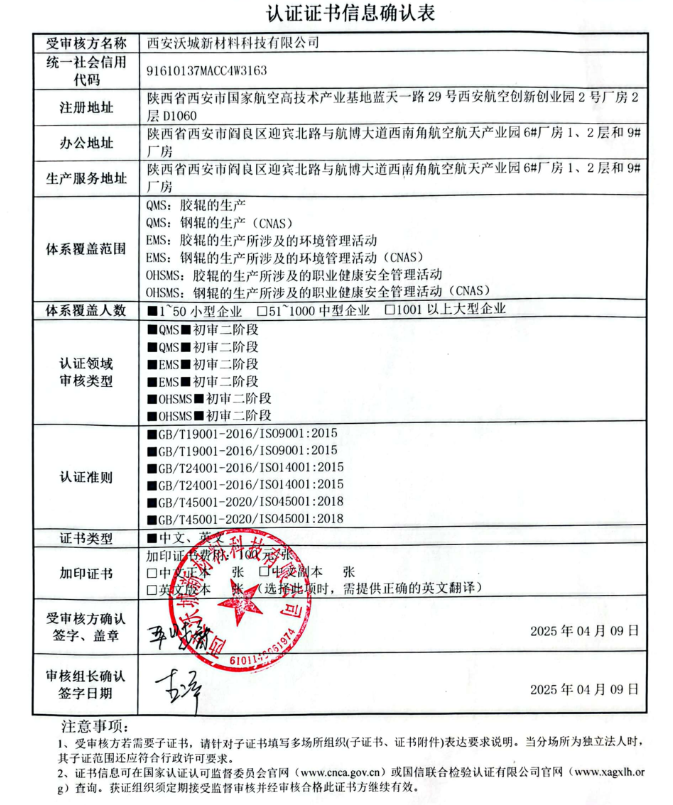

Audited Party Name: Xi'an Wocheng New Materials Technology Co., Ltd.

Audit Date: April 8, 2025 to April 9, 2025

Guoxin United Inspection and Certification Co., Ltd.

Address: Room 0501, Building 1, No. 140, Huancheng South Road, Beilin District, Xi'an City, Shaanxi Province

Market Development Department Tel: 029-87873725 Certification Audit Department Tel: 029-87873726

Email: gxlhrz@126.com Website: www.xagxlh.org

| Auditor Statement | |

| 1. Method Statement | 1) The audit report is based on sampling; 2) Because the audit findings and conclusions are made on the basis of sampling, there is a certain degree of uncertainty; 3) If the audited party has any objections to this report and the performance of the auditors, they can submit an appeal to Guoxin United Inspection and Certification Co., Ltd. |

| 2. Confidentiality Statement | 1) Respect the rights of the audited party, keep confidential any undisclosed information of the audited party and confidential information related to the audited party during the audit process, and not disclose it to any third party (except as required by law). |

| 3. Impartiality Statement | 1) Adhere to the auditor's code of conduct, maintain good professional ethics and conduct, and conduct audits impartially and objectively; 2) Comply with the management regulations and requirements of Guoxin United Inspection and Certification Co., Ltd. on certification impartiality; 3) Comply with the certification procedures, accurately and impartially reflect the conformity of the audited organization's management system with the certification criteria and the effectiveness of the system operation; 4) No certification-related consulting activities have been conducted for the audited party in the past two years; 5) There is no direct business, economic or other interest relationship with the audited party in the past two years; 6) The audit team is willing to assume legal responsibility for the above commitments. |

| 4. Declarant | All members of the audit team |

Audit Report

|

|||||||

| Audited Party Name | Xi'an Wocheng New Materials Technology Co., Ltd. | Contract Number | 2024-QQEESS1525 | ||||

| Audited Party Contact Person | Chen Xianglong | Telephone | 13923784651/13923784651 | ||||

| Registered Address | No. 29, Lantian Road, Xi'an Aviation Innovation and Entrepreneurship Park, Building 2, 2nd Floor, D1060, National Aviation High-tech Industrial Base, Xi'an City, Shaanxi Province | ||||||

| Office Address | Aerospace Industrial Park, Southwest Corner of Yingbin North Road and Hangbo Avenue, Yanliang District, Xi'an City, Shaanxi Province, Building No. 6, 1st and 2nd Floors, and Building No. 9 | ||||||

| Production Service Address | Aerospace Industrial Park, Southwest Corner of Yingbin North Road and Hangbo Avenue, Yanliang District, Xi'an City, Shaanxi Province, Building No. 6, 1st and 2nd Floors, and Building No. 9 | ||||||

| Audit Time | From the morning of April 8, 2025 to the afternoon of April 9, 2025, a total of 2 days. This audit is: 6.0 (person-days) | ||||||

| Audit Purpose | ■Initial Audit/Stage Two: To evaluate the audited party's management system's ability to meet relevant laws, regulations, and contract requirements, its compliance and effectiveness, to determine whether to recommend certification registration. | ||||||

| Audit Standard | ■GB/T19001-2016/ISO9001:2015 ■Audited party's management system documents ■Applicable laws, regulations and other requirements |

||||||

| Audit Method | On-site audit | ||||||

Audit Area Audit Type |

■QMS■ Initial Audit Stage Two ■QMS■ Initial Audit Stage Two ■EMS■ Initial Audit Stage Two ■EMS■ Initial Audit Stage Two ■OHSMS■ Initial Audit Stage Two ■OHSMS■ Initial Audit Stage Two |

||||||

| Combined Situation | ■QMS ■QMS ■EMS ■EMS ■OHSMS ■OHSMS | ||||||

| Audit Scope | QMS: Production of rubber rollers QMS: Production of steel rollers (CNAS) EMS: Environmental management activities involved in the production of rubber rollers EMS: Environmental management activities involved in the production of steel rollers (CNAS) OHSMS: Occupational health and safety management activities involved in the production of rubber rollers OHSMS: Occupational health and safety management activities involved in the production of steel rollers (CNAS) |

||||||

| Professional Code | QMS: 14.01.02; QMS: 17.10.02; EMS: 14.01.02; EMS: 17.10.02; OHSMS: 14.01.02; OHSMS: 17.10.02; |

||||||

| Risk Level | ■QMS: ■Medium Risk ■QMS: ■Medium Risk ■EMS: ■Medium Risk ■EMS: ■Medium Risk ■OHSMS: ■Medium Risk ■OHSMS: ■Medium Risk |

||||||

| Not applicable clause | 8.3 8.3 / / / /,Reason for non-applicability: ■Yes □No Is it reasonable and appropriate? | ||||||

| Number of people covered by the system | Actual number QMS: 23 QMS: 23 EMS: 23 EMS: 23 OHSMS: 23 OHSMS: 23 people, compared with the audit notification □Yes ■No changes |

||||||

| Audit team members and registration numbers | Serial number | Name | Certificate number | ||||

| A | Wang Erchan | 2024-N1QMS-1297704 2024-N1EMS-1297704 2024-N1OHSMS-1297704 |

|||||

| B | Duan Yabo | 2024-N1QMS-1363346 2024-N1EMS-1363346 2024-N1OHSMS-1363346 |

|||||

| C | Pang Yanxu | 2024-N1QMS-1357773 2024-N1EMS-1357773 2024-N1OHSMS-1357773 |

|||||

|

|||||||

1. Organization's licensing requirements (original documents must be checked) Provision of information and specific relevant content: A copy of the business license was provided, the business scope includes the certification scope, and the qualification is valid. 2. Brief description of the client (the client's situation, including its industry, main products/services, production capacity, business status, etc.; if the client is a multi-site, it should clearly state how many sites are included in the certification scope, the organizational structure and the relationship between them; if it is a multi-name, it should clearly state the relationship between the two named organizations): The company was established on March 28, 2023, with a registered capital of 10 million yuan. It is an independent company newly established by Wocheng Group. It is a manufacturing company that produces various steel rollers and rubber rollers, with 23 employees. Company office and production service address: No. 6 and No. 9 factory buildings, 1st and 2nd floors, Aerospace Industrial Park, southwest corner of Yingbin North Road and Hangbo Avenue, Yanliang District, Xi'an City, Shaanxi Province. The company's geographical location is superior, with convenient transportation, and the surrounding areas are all enterprises, with no environmentally sensitive areas. Main business scope: Metal structure manufacturing; Metal processing machinery manufacturing; General parts manufacturing; Machinery parts and components processing; Rubber product manufacturing, etc. Main customers: Xi'an Lantuo Electromechanical Equipment Co., Ltd., Jiangsu Taicheng Roller Co., Ltd., etc. Products are widely used in wide-format digital printers and new energy, copper foil, aluminum foil, glass, plastic film, textile, logistics transportation, papermaking machinery, mining transportation and production equipment industries. 3. Description of the audit department/site: The audit team, according to the planned arrangements, audited ■all□part of the functional departments and ■all□part of the sites. Unaudited sites: Unaudited departments: 4. Major change situations (if applicable): ■No major changes □Major changes, please describe the changes: □Reviewed the changed documents and implementation situation. □Did not review the changed documents and implementation situation, reason: 5. Document review situation (if applicable): ■Document audit was conducted, and a document audit report was issued to the auditee. □Document audit was not conducted. 6. Stage 1 audit situation (if applicable): ■A stage 1 ■on-site audit/□off-site audit was conducted, and a stage 1 audit report was issued to the auditee. □Stage 1 audit was not conducted. 7. Audit plan □Yes■No adjustments were made, if yes, please elaborate: 8. During the audit, □Yes■No uncertainties and/or obstacles that may affect the audit conclusions were encountered, if yes, please elaborate: |

|||||||

|

|||||||

1. Nonconformities 1) A total of 1 written nonconformities were issued in this audit, including 0 major nonconformities. 2) A total of nonconformities from the last audit, corrective actions effectively verified: □Effective □Partially effective ( ) □Ineffective. 2. Observation items 1) A total of 1 observation item was issued in this audit. 3. Management system documents and records of the auditee 1) Whether the management system documents comply with the certification criteria; 2) Confirm whether there are any inapplicable standard clauses; 3) Version of the management system documents; 4) Whether the management system documents cover the activities within the certification scope; 5) Whether the management system records are suitable for the business processes and truly reflect the operation of the management system; 6) Whether the control of documented information meets the requirements. Overview: The company's management system documents include: documented management manuals, procedural documents, various process management documents required to meet process planning, operation and control, management systems, emergency plans, etc., as well as external documents (laws, regulations and other requirements, relevant standards); relevant records, etc., basically meet the standard requirements. The system document version is: A/0, release and implementation date: 2024.9.1. The management system documents cover the activities within the certification scope; the management system records are suitable for the business processes and can basically truly reflect the operation of the management system. The company's quality, environmental, and occupational health and safety management system documents are established according to the GB/T19001-2016, GB/T24001-2016, and GB/T45001-2020 standards. When planning the management system, the organization's environment and the relevant stakeholders' needs and expectations related to the environmental and occupational health and safety management system, as well as measures to address risks and opportunities, were considered, and the management policy, objectives, responsibilities, outsourced processes (electroplating, heat treatment), and processes requiring confirmation (welding, aging) were clarified. It covers the activities within the certification scope, and the management system records are suitable for the business processes and can basically truly reflect the operation of the management system. The control of system documents and cultural information basically meets the requirements. 4. Suitability and effectiveness of management policy 1) The content of the management policy; 2) The suitability and effectiveness of the policy. Overview: Quality management policy: Strive for excellence, survival through quality; continuous improvement, development through reputation. Environmental management policy: Compliance with laws and regulations, pollution prevention, high efficiency and low consumption, environmental protection. Occupational health and safety management policy: Total participation, prevention first; safety first, health and safety. The above policies are included in the "Management Manual", have been documented, and are accessible to the public; basically suitable and effective. 5. Management objectives, indicators and management plans 1) The content of the management objectives of the auditee; 2) Whether the objectives are established in combination with the actual situation of the business process, and whether they are consistent with the management policy; 3) Whether there are methods to measure the achievement of objectives; 4) Whether the objectives have been achieved; 5) What are the established objective and indicator management plans; whether the content is sufficient; whether the implementation is effective. Overview: 1) The company's management objectives are as follows: Quality management objectives: Product first-time pass rate ≥98%; Customer satisfaction ≥95%; Environmental management objectives: Fire accidents: 0/year; Environmental pollution accidents: 0/year; Classification and disposal of solid waste, 100% control of hazardous waste; Occupational health and safety management objectives: 0 deaths and serious injuries; Electric shock accidents: 0/year; Minor injuries: less than 2/year; 2) The above objectives are established in combination with the actual situation of the business process and are consistent with the management policy; 3) The company's objectives are specific and measurable, and an objective assessment method has been established. 4) The objectives have been assessed regularly, and the management objectives of various departments have been achieved in stages since the system was put into operation. 5) "Quality Objectives and Implementation Planning Measures", "Environmental Objectives and Implementation Planning Measures", and "Occupational Health and Safety Objectives and Implementation Planning Measures" have been established. The content is basically sufficient and the implementation is effective. 6. Leadership role and commitment, organizational structure and responsibilities 1) Whether the top management has fulfilled its commitments; 2) Whether the setting of the organizational structure and the division of responsibilities are clear, reasonable, documented, and whether the functions of organizing and coordinating management work are clear; 3) Changes in organizational structure and responsibilities (where applicable). Overview: Top management is basically able to fulfill its commitments, the organizational structure and responsibilities are clear, and the functions of organizing and coordinating management work are clear, and have been documented. 7. Risks and opportunities 1) What are the risks and opportunities identified by the auditee? Is the content sufficient; 2) Whether the measures taken to address risks and opportunities are reasonable and effective. Overview: The organization has formulated a "Risk and Opportunity Control Procedure". The risk and opportunity identification considers the possibility and impact of risk occurrence. The identified risks and opportunities come from laws and regulations, standards, stakeholders, socio-economic factors, climate change, competitors, market operations, leadership, human resources, services and procurement, organizational efficiency, fire and electric shock and personal injury, etc. Risk and opportunity identification is sufficient, and the measures taken are basically reasonable and effective. 8. Compliance obligations Whether laws, regulations and other requirements (including product standards, service specifications, etc.) are comprehensively collected and communicated to relevant parties? Overview: The organization has identified and collected the laws, regulations and other requirements that the company needs to comply with. The collection is basically comprehensive. It is understood that the company regularly organizes internal learning of relevant laws and regulations, and can also communicate them to customers, suppliers and other relevant parties in a timely manner. 9. Resources 1) Sufficiency of human resource allocation and whether the capabilities of key personnel meet the requirements; sufficiency of training needs identification and implementation; 2) Configuration and maintenance of infrastructure; 3) Allocation, calibration and verification of monitoring and measurement resources; 4) Organization's knowledge acquisition and management, internal and external information exchange; Overview: 1) The organization's human resources are appropriately allocated, and the capabilities of key personnel meet the requirements. It has allocated various department managers, financial personnel, production managers, inspectors, process engineers, maintenance personnel, welding operators, machining operators, rubber mixing operators, vulcanization workers, etc. Upon spot check, personnel can provide proof of competency documents. Training needs identification is sufficient, and regular training has been conducted according to the plan and training records have been kept; 2) The company is equipped with sufficient infrastructure and equipment, such as standard production workshops, offices, meeting rooms, etc. It is equipped with ordinary lathes, CNC lathes, precision external cylindrical grinders, radial drilling machines, rigid support balancing machines, paper tape filter machines, laser marking machines, welding machines, circular cooling towers, single-beam bridge cranes (2T), vulcanization tanks, environmental protection exhaust gas treatment facilities, welding fume purifiers, industrial large fans, etc. It can meet the needs of the enterprise system operation, the infrastructure is in good condition, and regular maintenance can be carried out; during the audit, it was found that the inspection status of the special equipment vulcanization tank had expired, and one minor nonconformity was issued here. 3) The monitoring and measurement equipment involved in the activities within the scope of the company's certification includes: external diameter micrometer, vernier caliper, percentage head, internal diameter percentage meter, vernier depth gauge, strip level gauge, frame level gauge, as well as gas storage tank, vulcanization tank safety valve, pressure gauge, etc. Regular calibration has been carried out, and the current equipment status is normal. 4) The organization acquires and maintains the organization's knowledge through websites, books, meetings, knowledge/experience transfer, and training; internal and external information exchange is carried out through WeChat, telephone, meetings, and face-to-face communication. Currently, there are no nonconformities caused by poor internal and external information exchange. 10. Emergency preparedness and response Evaluation of emergency preparedness and response (including at least: sufficiency of identification of potential emergencies, reasonableness of emergency measures, effectiveness of emergency measures, and regular testing where feasible) Overview: The company has established emergency plans, including a "Fire Accident Emergency Response Plan," an "Electric Shock Accident On-site Handling Plan," a "Traffic Accident Emergency Response Plan," and a "Mechanical Injury Accident Handling Plan." Emergency plan training and drills have been organized. The established emergency measures are reasonable, have been regularly practiced and evaluated, and achieve their intended purpose. The control of emergency preparedness and response meets the requirements, and the established emergency measures are generally reasonable and effective. 11. Performance Monitoring 1) Compliance status, whether accidents/incidents/nonconformities have occurred and how they were resolved (including the local authorities' supervision of the audited party and the conclusions of the local regulatory authorities on the incidents), environmental impact assessment approvals, simultaneous implementation procedures, whether pollutant emissions meet standards, and hazardous waste disposal, etc. Overview: The company has organized personnel from various departments to conduct compliance assessments of environmental and safety laws, regulations, and other requirements in accordance with documented plans. The assessment shows that the company's environmental, occupational health, and safety management system complies with applicable laws, regulations, and other requirements. The company has complete environmental impact assessment approvals and simultaneous implementation procedures; the company implements a fixed pollution source discharge registration system. The main hazardous waste involved in the company is waste saponification liquid and waste oil products. The company has established a hazardous waste room and handles it according to the hazardous waste transfer system. According to our understanding, no major environmental, occupational health, or safety accidents or incidents have occurred since the system's operation. 2) National/Industry/Local Supervision and Inspection Status: Overview: Since the management system was implemented, no nonconformities have occurred during supervision and inspection; 3) Have any complaints occurred? If so, describe the complaint resolution and handling (including the effectiveness of corrective/preventive measures taken in response to the complaints): Overview: Through document verification and on-site inquiries, no complaints have been received from relevant parties (contractors, customers/users, higher-level regulatory authorities, and employees, etc.) regarding quality, environmental, or occupational health and safety since the system's operation. 4) Implementation of daily supervision and performance evaluation of the management system (environmental management system performance evaluation should refer to relevant data from environmental impact assessments and discharge permits): Overview: The company conducts daily supervision and performance evaluation through target assessments, internal audits, management reviews, and satisfaction surveys. All of the above measures have been implemented. 5) Description of the collection of external monitoring information and its compliance status: Overview: The company uses customer satisfaction surveys, emails, telephone follow-ups, and site visits to understand and collect customer feedback on the company's products and services. No major complaints have occurred since the management system's operation. 6) Planning and implementation evaluation of the most recent internal audit (should include at least the following aspects): ① Whether the planning time interval is within 12 months: ② Whether the implementation process meets the requirements, including the following aspects: a) Whether the implementation content conforms to the standards and the actual situation of the enterprise: b) Whether nonconformities have been identified, and whether the closure of nonconformities reflects the content of corrective actions; please describe in detail the specific content of the identified nonconformities and the implementation of corrective actions for nonconformity remediation; c) The implementation status of corrective actions taken for nonconformities identified in the previous audit: d) Whether the measures taken for recurring nonconformities are effective: e) Whether the audit report describes the actual situation of the enterprise's audit (whether there are any similar phenomena in the main content), and whether it is distributed as required. Overview: The company has compiled an "Internal Audit Procedure," and the planning interval between two internal audits does not exceed one year. A set of materials from the most recent internal audit is provided. The internal audit was conducted from January 8-9, 2025. The audit team leader was Yan Xiaozhi, and the team member was Zhang Min. After communication, it was confirmed that both auditors had received internal auditor training and have the ability to independently conduct internal audits. The internal audit implementation process generally proceeded as planned. Documents such as the "Internal Audit Plan," "Meeting Sign-in Sheet," "Internal Audit Checklist," "Nonconformity Report," and "Internal Audit Report" were reviewed. The internal audit identified one minor nonconformity report (related to clause ES9.1.1 of the Comprehensive Management Department), with no major nonconformities. The responsible department has conducted a root cause analysis and implemented corrective and preventive actions. The corrections have been completed and verified by the internal audit team. Audit conclusion: The company's quality, environmental, and occupational health and safety management system generally meets the standard and system requirements, and its operation is generally effective. 7) Planning and implementation evaluation of the management review (should include at least the following aspects): ① Planning time interval: ② Whether the implementation process proceeded according to the plan: ③ Management review inputs: ④ Management review outputs and conclusions: Overview: The company has compiled a "Management Review Control Procedure." The general manager presides over the management review activities. The company conducts at least one management review per year. If specified situations arise, the general manager may decide to increase the frequency of management reviews. A set of materials from the most recent management review is provided, dated February 14, 2025. The "Management Review Plan," "Meeting Sign-in Sheet," "Internal Audit Report," and "Quality, Environmental, and Occupational Health and Safety Management Analysis Report" were reviewed. The management review was implemented as planned, and the inputs were generally sufficient. The management review output was provided in the form of a "Management Review Report," which provided the review conclusions and one improvement requirement. The management review conclusion is that the company's policies and objectives are suitable for the company's actual situation, the system operation is appropriate, sufficient, and effective, and the management system's planning does not require changes. The company has developed an improvement plan for the improvement requirements. The company retains written information on the management review. Management review control generally meets the standard requirements. 12. Continuous Improvement Content of continuous improvement and performance achieved: Overview: The company identifies areas for improvement in the system's operation through satisfaction surveys, internal audits, management reviews, risk and opportunity identification and response, and is able to continuously improve. Currently, the system is operating well and can continuously meet the needs of relevant parties. 13. Use of certification certificates and logos and external publicity (where applicable): / 1) Use of certification certificates and logos: 2) Whether certification certificates and logos were used during the suspension period (where applicable): 3) Whether the organization's marketing materials were modified after the scope of certification was reduced (where applicable): Overview: 14. Other 1) Are there any unresolved disagreements or unresolved issues: No 2) Restoration of certification audit (applicable when suspension is lifted): ① Has the reason for suspension been eliminated: ② Did the use of the certificate during the suspension period meet the requirements: |

|||||||

|

1. Product execution standards and inspection standards: Overview: *Involving the production of steel rollers, relevant standards such as: "Product Geometric Technical Specifications (GPS) Geometric Tolerances Shape, Direction, Position and Runout Tolerance Annotation GB/T1182-2018", "Product Geometric Specifications (GPS)", "Surface Roughness Profile Method Surface Roughness Parameters and Their Values GB/T1031-2009", "Shape and Position Tolerances Unnoted Tolerance Values GB/T 1184-1996", "Key Technical Conditions GB/T 1568-2008", "General Tolerances General Deviations of Linear and Angular Dimensions Without Tolerance Lines GB/T1804-2000", "Product Geometric Technical Specifications (GPS) Geometric Elements Part 1: Basic Terms and Definitions GB/T18780.1-2002", "Product Geometric Technical Specifications (GPS) Geometric Tolerances Detection and Verification GB/T1958-2017", "Mechanical Drawing Dimensioning GB/T4458.4-2003", "Mechanical Drawing Dimensional Tolerances and Fits GB/T4458.5-2003", "Mechanical Drawing Center Hole Representation GB/T4459.5-1999", "Mechanical Drawing Schematic Diagram of Mechanism Movement Use Graphic Symbols GB/T4460-2013", "Mechanical Drawing Threads and Threaded Fasteners GB/T4459.1-1995", "Remanufacturing Mechanical Processing Technical Specifications GB/T 33947-2017", "Mechanical Processing Process Parameter Representation JB/T 12392-2015", "Engineering Machinery Mechanical Processing Parts General Technical Conditions JB/T 5936-2018", etc. *Involving the production of rubber rollers: "Rubber Roller Zhao (P.J) Hardness Meter Technical Conditions HG/T 2644-2011", "Rubber Rollers Part 2: Polyurethane Rubber Rollers HG/T 2697-2017", "Laminating Machine Rubber Rollers HG/T 5599-2019", "Rubber or Plastic Covered Rollers Specification Part 1: Hardness Requirements GB/T 39697.1-2020", "Rubber or Plastic Covered Rollers Specification Part 2: Surface Properties GB/T 39697.2-2020" 2. Whether the planning and control of product and service design and development activities meet the requirements: Overview: Not applicable 3. Control of important process implementation (The product realization process should be described according to the process execution situation, the process and control situation that needs to be confirmed, the key process and control situation, if it includes the control situation of the relatively dangerous sub-projects, construction machinery and equipment in EC9000, a detailed description should be made): Overview: *Involving the production of steel rollers: Raw materials → Shearing → Rough turning → Boring → Balance inspection → Baking and welding → Stress relief → Turning → Secondary re-inspection and balancing → Fine grinding → Polishing → Inspection and packaging The process that needs to be confirmed is welding, and the outsourced process is heat treatment and electroplating. The "procurement product inspection record", raw material quality certificates, "production task order", "first-piece inspection order", "product process flow card", "finished product factory inspection report", "factory inspection report", etc., are retained as evidence that the process execution meets the requirements, and the process operation is effective. *Involving the production of rubber rollers: Steel pipe → Cutting → ★Welding → Machining → Wiping → Glue application Wrapping → ★Curing → Grinding → Grooving → Packaging. Batching → Feeding → Mixing → Filtering → Kneading → Testing The process that needs to be confirmed is curing, and there is no outsourced process. The "procurement product inspection record", raw material quality certificates, "production task order", "first-piece inspection order", "product process flow card", "finished product factory inspection report", "factory inspection report", etc., are retained as evidence that the process execution meets the requirements, and the process operation is effective. 4. Determination, review and change management of product and service requirements, selection, evaluation, monitoring, verification and re-evaluation of external suppliers, contractors and outsourcing parties, and change management: Overview: The company's product and project requirements are fully communicated with customers before the contract is signed. Relevant requirements will be included in the contract. All contracts will be reviewed before signing. Contracts can only be signed after it has been determined that the relevant customer requirements can be met; the company comprehensively considers various aspects of external suppliers, including infrastructure, certification, quality, price, timeliness, service, and integrity, and uses the form of supplier evaluation to evaluate and select relevant suppliers. Relevant evidence is retained on site. |

|

1. Identification and evaluation of environmental factors 1) Sufficiency of environmental factor identification (including whether the life cycle perspective is considered): 2) Reasonableness and sufficiency of the evaluation of important environmental factors: Overview: 1) The company has identified environmental factors and considered the life cycle perspective; environmental factor identification is basically sufficient; 2) The company uses a quantitative scoring method to evaluate environmental factors, determines important environmental factors, and forms an "important environmental factor list". The evaluation of important environmental factors is basically reasonable and sufficient. 2. Control measures (Including environmental objectives and management plans, contingency plans, operating rules, etc.) planning and implementation: 1) Compliance of the established control measures: 2) Suitability of the established control measures to important environmental factors: 3) Implementation evaluation of control measures: Overview: 1) The control measures (including environmental objectives/indicators and management plans, operational control, and the development of plans) formulated by the organization are compliant and basically meet the actual needs of the enterprise. 2) The established control measures are suitable for the important environmental factors identified by the enterprise. 3) The company verifies the effectiveness of the implementation of control measures through environmental operation inspections, emergency drills and evaluations, internal audits, management reviews, and compliance evaluations. 3. Response to external information : Overview: The enterprise has established good communication channels with external stakeholders, and the enterprise can actively and promptly respond to external information. Currently, there are no non-conformances caused by untimely response to external information. 4. Event, nonconformity corrective action formulation and implementation : Overview: The enterprise can actively correct events and nonconformances and formulate corrective actions. There are basically no environmental nonconformances and accidents. |

|

1. Identification and evaluation of hazards 1) Sufficiency of hazard/hazard factor identification: 2) Reasonableness and sufficiency of major hazard source/hazard factor evaluation: Overview: 1) The organization's identification of hazard sources/hazard factors is thorough. 2) Based on the hazard level of the hazard sources, the company has formed a "list of key controlled hazard sources and OH&S risks." The measures are generally reasonable and sufficient. 2. Planning and implementation of control measures 1) Compliance and suitability of the control measures established: 2) Implementation of control measures: Overview: 1) The control measures established by the company are compliant and generally meet the company's actual needs. 2) The company verifies the effectiveness of the implemented control measures through safety operation inspections, emergency drills and evaluations, internal audits, management reviews, and compliance evaluations. 3. Participation of personnel and implementation of consultation : Overview: Employees in various departments of the company can participate in and consult on matters related to occupational health and safety management within their departments. They comply with the company's established occupational health and safety management policies and regulations, achieving the company's and department's occupational health and safety management objectives. The company's occupational health and safety representatives are generally clear about and able to fulfill their relevant responsibilities. They can collect employee opinions and suggestions, and represent employees at the company level for feedback, participation, and consultation. 4. Event, nonconformity corrective action formulation and implementation : Overview: The company actively corrects events and nonconformities and establishes corrective actions. According to our understanding, no environmental, occupational health, or safety incidents or accidents have occurred since the management system was implemented. |

|

|

|

|

|

|

| Initial Audit | ■Basically meets the standard requirements and operates effectively. The organization should also complete the rectification of all nonconformities within the specified time limit. After verification of effectiveness, certification registration is recommended. |

|

|

| Follow-up on the rectification of items requiring observation. | |

Previous article

Next article

Previous article

Next article

Latest developments

2025-08-04

Enhancing Electronics Manufacturing Processes through the Use of EVA Rollers

Enhancing Electronics Manufacturing Processes through the Use of EVA Rollers Table of Contents 1. Introduction to EVA Rollers in Electronics Manufacturing 2. Understanding the Role of EVA Rollers in Manufacturing 2.1 What are EVA Rollers? 2.2 Key Characteristics of EVA Rollers 3. Benefits of Using EVA Rollers in Electronics Manufacturing 3.1 Increased Efficiency 3.2 Enhanced Product Quality 3.3 Co

2024-11-20

The application of vacuum rollers in the packaging industry.

The vacuum roller creates a vacuum environment on the surface of the roller, allowing objects to be firmly attached to the roller, thereby securing the objects.

2024-11-20

Selection of Adhesives for Polyurethane Rubber Rollers

Rubber rollers are cylindrical products made of rubber that has been vulcanized, possessing sufficient surface viscosity.